Ukucaciswa kwedayizi kuhlobene nohlobo nokujiya kwezinto ezigxivizwayo.Izikhala ezingenangqondo zingadala izinkinga ezilandelayo:

(1) Uma igebe likhulu kakhulu, i-burr yesitembu sokusebenza sikhulu uma kuqhathaniswa nekhwalithi yokugxiviza impofu.Uma igebe lincane, nakuba izinga lokubhoboza lingcono, kodwa ukugqoka kwefa kuyingozi kakhulu, kunciphisa kakhulu impilo yesevisi yokufa, futhi kulula ukubangela ukuphuka kwe-punch.

(2) igebe likhulu kakhulu noma lincane kakhulu kulula ukukhiqiza adhesion phezu impahla Punch, okuholela isitembu ngezinto.Ukuvunyelwa okuncane kakhulu kulula ukwenza i-vacuum phakathi kwephansi le-punch kanye neshidi lensimbi nokuphindaphinda kwemfucuza.

(3) imvume enengqondo ingandisa impilo yesikhunta, umphumela wokukhipha muhle, unciphise i-burr kanye ne-flanging, ipuleti lihlale lihlanzekile, indawo yokuvula ihambisana ngeke iklwebhe ipuleti, inciphise inani lokugaya, gcina ipuleti liqondile, indawo yokufaka isibhakela enembile. .

CNC Punch die, CNC Punch ithuluzi, CNC die

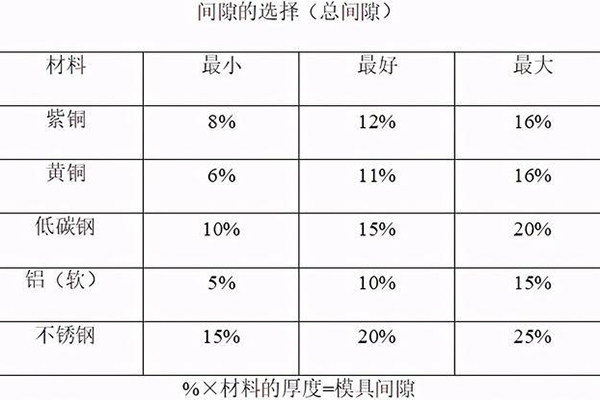

Sicela ubhekisele eshadini ukuze ukhethe ukususa isikhunta (idatha esethebulani ingamaphesenti)

(1) Uma igebe likhulu kakhulu, i-burr yesitembu sokusebenza sikhulu uma kuqhathaniswa nekhwalithi yokugxiviza impofu.Uma igebe lincane, nakuba izinga lokubhoboza lingcono, kodwa ukugqoka kwefa kuyingozi kakhulu, kunciphisa kakhulu impilo yesevisi yokufa, futhi kulula ukubangela ukuphuka kwe-punch.

(2) igebe likhulu kakhulu noma lincane kakhulu kulula ukukhiqiza adhesion phezu impahla Punch, okuholela isitembu ngezinto.Ukuvunyelwa okuncane kakhulu kulula ukwenza i-vacuum phakathi kwephansi le-punch kanye neshidi lensimbi nokuphindaphinda kwemfucuza.

(3) imvume enengqondo ingandisa impilo yesikhunta, umphumela wokukhipha muhle, unciphise i-burr kanye ne-flanging, ipuleti lihlale lihlanzekile, indawo yokuvula ihambisana ngeke iklwebhe ipuleti, inciphise inani lokugaya, gcina ipuleti liqondile, indawo yokufaka isibhakela enembile. .

CNC Punch die, CNC Punch ithuluzi, CNC die

Sicela ubhekisele eshadini ukuze ukhethe ukususa isikhunta (idatha esethebulani ingamaphesenti)

Ulwazi lwemboni:

1. Ungahlulela kanjani iphutha lokunemba kwe-NC lathe

Imboni ye-automatic CNC lathe manje ibhekene nenkinga enkulu, ukungeniswa kwethuluzi lomshini we-CNC eliphezulu kakhulu.Kusukela kudatha efanelekile yokungeniswa kwethuluzi lomshini we-CNC, kusukela ngoNovemba 2012, ukungenisa kwethuluzi lomshini we-CNC laseChina lilonke libonisa ukwehla, kodwa intengo yokungenisa ibilokhu ikhuphuka, okungabonisa ukuthi ukuthengwa okuphezulu kwethuluzi lomshini we-CNC kuyaqhubeka nokukhuphuka.Ungasho ukuthi umshini ngokwawo, ithuluzi lomshini we-CNC liwumkhiqizo oyinhloko wokuzenzakalelayo kwethuluzi lomshini kanye nobuhlakani, izinga lesistimu yalo ye-CNC liyinkomba ebalulekile yokunquma izinga le-lathe ye-CNC ezenzakalelayo.Kodwa-ke, ama-90% wezinhlelo ze-CNC zasekhaya kufanele zingeniswe kwamanye amazwe.

2. Isebenza kanjani i-CNC lathe

I-CNC lathe ingacushwa ngezinhlobo ezimbili zetafula lommese: (1) thayipha ithebula lommese ngokuthuthuka kanye nomklamo womkhiqizi we-CNC, ukusetshenziswa kwekholethi nakho kuwuhlobo.Inzuzo yalolu hlobo lwetafula lommese yizindleko eziphansi zokukhiqiza nokukhiqiza, kodwa ukuntuleka kokusebenziseka (2) ithebula lommese lomhlaba wonke elisekelwe ekucacisweni kwendawo yonke (njenge-VDI, i-French Institute of Technical Engineers) kanye nokukhiqizwa kwetafula lommese. , abakhiqizi bezintambo ze-CNC bangakhetha futhi bahlomise ngokuya ngendima ye-CNC lathe amalungiselelo.1. Amandla okukhiqiza we-CNC lathe anganwetshwa kakhulu ngemva kokuba itafula lokusika elijikelezayo lifakwe etafuleni lokusika le-rotary.Isibonelo, ukusetshenziswa kwetafula lokusika elijikelezayo ukwenza ukumba kwe-radial nokusika i-axial groove.2. I-CNC lathe CNC blade ku-CNC lathe noma izingxenye zokugaya zesikhungo somshini wokukhiqiza, kufanele zisekelwe esakhiweni se-CNC lathe futhi ingafakwa enanini eliphelele le-CNC blade, ucwaningo olusebenzayo nolwesayensi lokwaba i-NC blade ezingxenyeni zetafula lamathuluzi. , futhi unake ukuvimbela i-CNC blade ku-static nasemsebenzini, Ukugxambukela phakathi kwe-NC blade ne-NC lathe, i-NC blade ne-workpiece kanye ne-NC blade yayo.

Umsebenzi ungahlukaniswa cishe ube yizinqubo ezilandelayo: 1. Yenza izindlela zokubala izinombolo kanye namasu okucubungula ngokuya ngokukhiqiza nokucubungula okuqukethwe kobuchwepheshe okubalulwe engxenyeni yemidwebo.Idizayini yokusabalalisa nokugeleza kohlelo.2. Uhlelo lwethuluzi lomshini wokulawula izinombolo lugeleza ngokuya ngezidingo zezinombolo zokulawula i-lathe yefomethi yefayela lokugeleza kohlelo, kanye nerekhodi elinemininingwane ngendlela yokubhala amakhodi emishinini yokugcina ephathwayo, ngokuya ngokokufaka (ukukhiqizwa ngesandla, ukudluliswa kwekhompyutha, njll. .) Indlela, okuqukethwe kokugeleza kohlelo lokukhiqiza nokucubungula ukuya kumshini wethuluzi lokulawula izinombolo.3. Ukugeleza kohlelo lwethuluzi lomshini we-NC (ikhodi ye-NC) eyamukelwe ithuluzi lomshini we-NC, ikhodi ye-NC iguqulelwa noma yenziwe ngesandla ngumhleli wesofthiwe kusofthiwe ye-CAM, iwulwazi lwedatha yombhalo, isisho sibonakala kakhudlwana, kulula ukusisebenzisa. iqondwe ngokushesha ngumhleli wesofthiwe, kodwa ayikwazi ukusetshenziswa ngokushesha ekucushweni kwehadiwe.Ithuluzi lomshini we-NC Imishini ye-NC enekhodi "ukuhumusha kwesiShayina" okokusebenza kokufaka amakhodi, ukufakwa kwekhodi kwemishini yakhiwa ama-0 s no-1 s wamafayela kanambambili, bese ishintsha ukuze isebenzise isignali yesignali yedatha yokufaneleka engu-X kanye no-Z, kanye namanye amasiginali wedatha asizayo, futhi izixazululo ngendlela yesiginali ehlukile ethekwini lokuphuma kwemishini yamathuluzi omshini we-NC, uhlelo lokulawula i-servo ukwenza lo mkhuba.

3. Ngenkathi yezimvula, kufanele zigcinwe kanjani izinsimbi ze-CNC ezizenzakalelayo

Ngenkathi yezimvula, ukugcinwa nokugcinwa kwemishini yemishini kubaluleke kakhulu, ngoba esimweni sezulu esinjalo, imishini ivame ukwehluleka, futhi izindawo eziningi zaseningizimu yeShayina zinemvula enkulu, ngisho nezinye izindawo zinezikhukhula.Lapha, sethula indlela yokulondoloza i-lathe ye-CNC ezenzakalelayo ngenkathi yemvula?

I-Automatic CNC lathe iyithuluzi lokukhiqiza elinembayo, inezidingo ezintathu ezibalulekile ezilandelayo zemvelo:

(1) beka isikhundla se-lathe ye-CNC okuzenzakalelayo kumgomo womthombo wokudlidliza, futhi awukwazi ukuba nokukhanya kwelanga okuqondile, umoya nawo uyadingeka ukuze wome;

(2) Izidingo zokuphakelwa kukagesi, amandla kagesi kumele azinze;

(3) Izimfuneko zokushisa nomswakama, izinga lokushisa akufanele libe ngaphansi kuka-30 ℃, umswakama akufanele ube ngaphansi kuka-80%.Kungani sidinga izimo ezinjalo?Vumela i-xiaobian ikucacisele ukudideka: ukudlidliza kokuqala kuzothinta ngqo ikhwalithi yesiqeshana somsebenzi, isikhathi eside sokuchayeka kwelanga ekulawuleni ukunemba kwe-automatic CNC lathe nakho kuyathinteka;Okwesibili, ukuqina kwamandla kagesi kungenye yezinto ezibalulekile zokuqinisekisa umsebenzi ojwayelekile we-lathe ye-CNC ezenzakalelayo, ngoba izingxenye ze-automatic CNC lathe nazo ziyizingxenye ezinembayo, ukungazinzi kwamandla kagesi kulula ukubangela ukulimala ezingxenyeni eziqondile, okuholela ku-othomathikhi ye-CNC lathe ayikwazi ukusebenza kahle;Ngemuva kwalokho, izinga lokushisa nomswakama nakho kuyisici esibalulekile sokuqinisekisa ukusebenza okuvamile kwezingxenye ze-lathe ze-CNC ezizenzakalelayo, izinga lokushisa eliphezulu kakhulu nomswakama kuzoholela ekuphileni okuncishisiwe kwezingxenye zesistimu, ukwehluleka okukhulayo, ngisho nokwenza isibopho sothuli ebhodini lesifunda, okuholela ekutheni isifunda esifushane.

Landela ngokuqinile ikhodi kagesi

1. I-lathe ye-CNC ezenzakalelayo kufanele idingeke ngokuqinile ukuze ufinyelele phansi, kanye nokusetshenziswa kwepulaki yamandla amathathu-core, ukunciphisa ukuphazamiseka kwe-electrostatic, ukuthuthukisa ukuqina komshini kanye nokuvikelwa komsebenzisi.Ehlobo, ngenxa yokusetshenziswa kukagesi ngokweqile kanye nenkathi yemvula, ngokuvamile kuzoba nokungaqini kahle kwamandla kagesi kagesi, njll., okuholela ekuhlulekeni, ngisho nokushisa umshayeli nezinye izingxenye.Kunconywa ukuthenga i-voltage regulator yemodeli ehambisanayo.

2. Thuthukisa ukusetshenziswa kwe-CNC okuzenzakalelayo kwe-CNC lathe, i-CNC yokulawula izinombolo uma izinga lokugijima lingekho phezulu, ngaphezu kwemali, umphumela wawungaphansi kokukhiqiza kabusha, kodwa futhi ukukhathazeka ngento isikhathi sewaranti, ngoba i-CNC automatic CNC Imishini ye-lathe inesikhathi sewaranti, umsebenzisi kufanele asebenzise umshini kulesi sikhathi, ingxenye encane ivezwe ngokushesha, Izolahlwa ngaphansi kwewaranti.Uma ingasetshenziswa isikhathi eside, ukuwohloka noma ukulimala kwezingxenye ze-elekthronikhi kungase kusheshiswe ngenxa yokuswakama nezinye izizathu.Ikakhulukazi ngenkathi yemvula, futhi ufuna ukusebenzisa umshini ngendlela efanele.

3. I-CNC automatic lathe ye-CNC kufanele isetshenziswe endaweni ekahle ngoba umoya unomswakama ngenkathi yemvula.Kulula ukuba manzi emoyeni oswakeme futhi wehluleke.Futhi unake imininingwane emsebenzini, ngakho-ke qaphela ukuthi ungalethi izambulela endaweni yokukhiqiza, ushintshe izicathulo, njll.

4. Yiziphi izingxenye ezibalulekile ze-othomathikhi ye-CNC lathe machini

I-1, Ibhokisi eliphethe i-CNC lathe spindle elizenzakalelayo: ibhokisi elinomshini wokuphotha eliphakathi nendawo eligxilwe ekugcineni kwesokunxele sombhede.Idlulisa ukunyakaza kokufaneleka okujikelezayo kwenjini iye kubheringi yokuphotha, bese iphusha ucezu lokusebenza ukuze lujikeleze ndawonye ngokuya ngokulungiswa.Ngokushintsha indawo ye-rocker ebhokisini, i-spindle bear ingathola izilinganiso ezihlukahlukene zesivinini zokuhle nokuhlehlayo.

2, Ibhokisi lamathuluzi: ibhokisi lamathuluzi lesikhungo somshini ligxiliswe ngaphambili kwesokunxele nangaphansi kombhede.Ngokusho kwesondo elilengayo, ukunyakaza kokufaneleka okujikelezayo kwebheringi yokuphotha kudluliselwa kusikulufu sebhola noma isikulufu esikhanyayo.Shintsha indawo ye-rocker ebhokisini, ingashintsha isilinganiso sesivinini se-ball screw noma isikulufu esikhanyayo, bese ufinyelela umgomo wokushintsha i-pitch yezinyo noma isivinini sokusika.

3, Ibhokisi lebhodi lamaslayidi: ibhokisi lebhodi lama-slide elimiswe ngaphandle kwesihlalo sombhede, nesihlalo sombhede sihlangene embhedeni womzimba wesitimela sokunyakaza okuphindaphindiwe okuphindaphindiwe.Ngokusho kwayo isikulufu sebhola noma ukufaneleka kokuzungezisa kwebha elilula kusihlalo sombhede, ukufaneleka kommese osonte kabili wepuleti lokuhamba.Ingxenye ye-rocker ebhokisini lokuguqula ingasebenzisa ukunyakaza kokuqina kwethuluzi le-lathe okuma mpo noma okuvundlile (umumo wokunyakaza kokufaneleka, ukuqala noma ukuma).

4. I-side rack: I-side rack ifakwe ohlangothini lwesobunxele lombhede.Ifakwe igiya lokudlulisela elishintshashintshayo (isondo elilengayo), elidlulisa ukunyakaza kokujikeleza kokuqina kwebheringi yokuphotha ebhokisini lamathuluzi.Lungisa igiya lokudlulisela ku-rack yesondo elilengayo futhi usebenzisane nebhokisi lokusika ukuze uhlanganise imicu enephimbo ehlukile.

5, Ithebula lommese: ithebula lommese eligxilwe ekudonseni okuncane, elisetshenziselwa izikhali nethuluzi le-lathe lemishini.

I-6, i-Precision CNC lathe pallet: i-pallet ihlanganisa isihlalo sombhede, ipuleti le-warping eliphindwe kabili, isondo nepuleti elincane le-warping eliphindwe kabili izingxenye ezine.Isihlalo sombhede sigxunyekwe kuma-slide rails ngaphandle komzimba wombhede futhi singanyakaziswa mpo eduze kwama-slide reils omzimba wombhede.Ipuleti le-warping eliphindwe kabili lingahamba livundlile eduze nomzila we-dovetail slide ekugcineni okuphezulu kwesihlalo sombhede;Ipuleti elincane le-warping lingahamba liqonde ku-dovetail slide wesitimela phezulu kwesondo.Ngemuva kokuthi isondo lizungeza i-engeli eyodwa yokubuka, ipuleti elincane eligoqayo lingaphusha ummese ukuze uhambe ngokudayagonali, osetshenziselwa ukugaya izindawo ezimfishane zangaphakathi nezingaphandle eziyikhoyili.

7, Ithuluzi lokuphumula le-Lathe: isihlalo somsila sifakwe kumzila we-slide weqembu lombhede, futhi singanyakaziswa ngokuqondile eduze komzila we-slide wombhede.Imbobo yekhoni yokucaciswa komkhono kumphathi wethuluzi le-lathe ingafakwa, i-twist drill, i-reamer, impompi neminye imimese nezinye izesekeli, ezisetshenziselwa ukusekela ucezu lomsebenzi womkhiqizo, ukubhola, ukubhora, ukucofa nokunye.

8, Umzimba wombhede: umzimba wombhede uyisisekelo sokusekela i-CNC lathe.Igxiliwe emilenzeni yombhede wesokunxele nesokudla, esetshenziselwa ukusekela izingxenye eziyinhloko ze-lathe side, futhi ibenze balondoloze isikhundla esihlobene nesihlobo emsebenzini.Amaqembu amabili ama-slide rails emzimbeni wombhede anikeza isiqondiso sokunyakaza okuqondile kwesihlalo sombhede kanye nendawo yokuphumula yamathuluzi e-lathe.

9, Isikulufu sebhola: ukhiye we-ball screw wentambo yokugaya, ingenye yezingxenye ezibalulekile zonqenqema lwe-lathe.Ukuze uhlale ulondoloza ukunemba kwesikulufu sebhola, ngokuvamile akudingekile ukusebenzisa isikulufu sebhola esikhungweni se-automatic cutting.ng?

Isikhathi sokuthumela: Aug-12-2022